SUA has collaboration agreements with audited factories across China, covering a wide spectrum of technologies, industries, and project scales. Partnering with us provides direct access to the advantages of the Chinese market, extended by our technical experience and complete project management for the safety and reduced complexity of your operations.

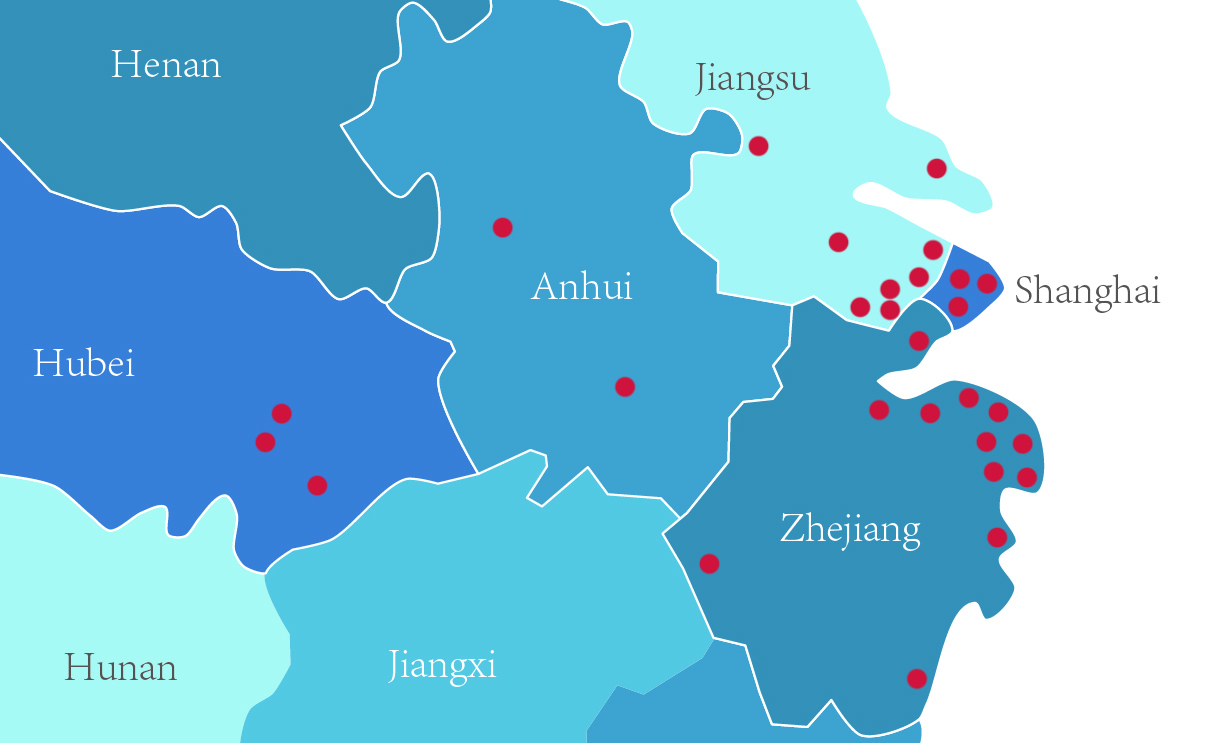

A: the Yangtze River Delta region

Our supply base in the Yangtze River Delta is strategically concentrated, featuring around 15-20 specialized manufacturers. Main products include plastic injection molds, die casting, high-precision tools, 3D printing, and component production.

A key logistical advantage is that most suppliers are located within a two-hour radius of Shanghai, ensuring exceptional responsiveness. This proximity, combined with the region’s manufacturing clusters and logistic centers, translates into high production capacity and competitive cost opportunities for our clients.

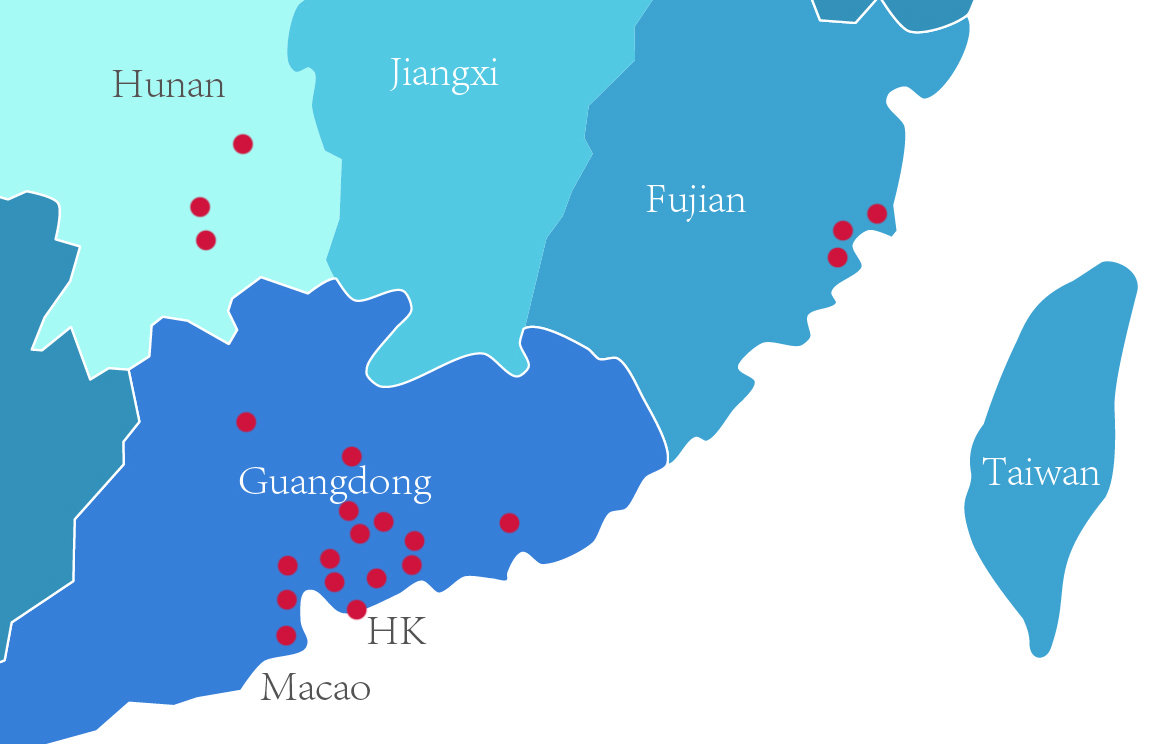

B: the Pearl River Delta region

Our Pearl River Delta supply network comprises a seasoned group of approximately 15-20 manufacturers with extended expertise. They cover multiple technologies including plastic injection molds, stamping tools, electronics, design services and specialized machinery.

The strength of this network lies in its deep-rooted experience and established operations. We partner with well-rounded factories situated within the region's extensive industrial parks. This mature ecosystem ensures access to advanced manufacturing capabilities, supply chain resilience and scalability for diverse project requirements.

C: the North China region

Our strategic partner network in Northern China consists of a select group of approximately 5-10 specialized manufacturers. These partners are primarily focused on the production of automotive components, precision foundry and die casting work and supplying the railway industry, with deep expertise in manufacturing serial components.

The hallmark of this network is its extensive experience in large-scale production. Our partners operate within the established heavy-industry hubs of the region, providing access to robust capabilities for serial production, high-volume orders, and components that meet strict durability and performance standards.

SUA has collaboration agreements with audited factories across China, covering a wide spectrum of technologies, industries, and project scales. Partnering with us provides direct access to the advantages of the Chinese market, extended by our technical experience and complete project management for the safety and reduced complexity of your operations.

A: the Yangtze River Delta region

Our supply base in the Yangtze River Delta is strategically concentrated, featuring around 15-20 specialized manufacturers. Main products include plastic injection molds, die casting, high-precision tools, 3D printing, and component production.

A key logistical advantage is that most suppliers are located within a two-hour radius of Shanghai, ensuring exceptional responsiveness. This proximity, combined with the region’s manufacturing clusters and logistic centers, translates into high production capacity and competitive cost opportunities for our clients.

B: the Pearl River Delta region

Our Pearl River Delta supply network comprises a seasoned group of approximately 15-20 manufacturers with extended expertise. They cover multiple technologies including plastic injection molds, stamping tools, electronics, design services and specialized machinery.

The strength of this network lies in its deep-rooted experience and established operations. We partner with well-rounded factories situated within the region's extensive industrial parks. This mature ecosystem ensures access to advanced manufacturing capabilities, supply chain resilience and scalability for diverse project requirements.

C: the North China region

Our strategic partner network in Northern China consists of a select group of approximately 5-10 specialized manufacturers. These partners are primarily focused on the production of automotive components, precision foundry and die casting work and supplying the railway industry, with deep expertise in manufacturing serial components.

The hallmark of this network is its extensive experience in large-scale production. Our partners operate within the established heavy-industry hubs of the region, providing access to robust capabilities for serial production, high-volume orders, and components that meet strict durability and performance standards.